Blue 980 Reinforced Plastic Steel Tile

Key words:

Key words:

Blue 980 Reinforced Plastic Steel Tile

Classification:

Related Description

980 Reinforced Plastic Steel Tile Deshijia APVC-A Series

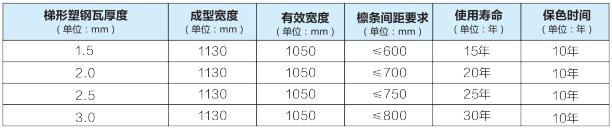

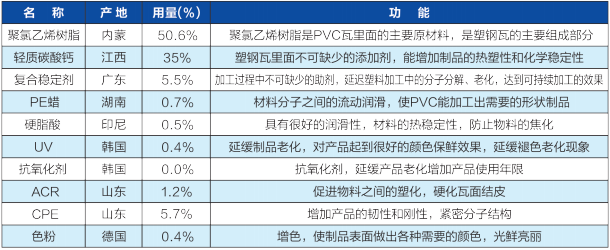

Deshijia APVC-A Series: This product uses polyvinyl chloride resin (PVC) as the main raw material, covered with red clay, UV stabilizers, antioxidants, etc. The surface layer is made with a special formula, scientifically proportioned and produced using advanced technology, significantly improving the product's oxygen index, surface hardness, strength, and resistance to acid and alkali corrosion, delaying aging and fading of the product.

Deshijia APVC-A Series

980 Reinforced Plastic Steel Tile Deshijia PVC Series

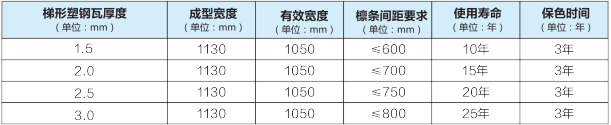

Deshijia PVC Series: This product uses polyvinyl chloride resin (PVC) as the main raw material, covered with red clay, UV stabilizers, antioxidants, etc. The surface layer is made with a special formula, scientifically proportioned and produced using advanced technology, significantly improving the product's oxygen index, surface hardness, strength, and resistance to acid and alkali corrosion, delaying aging and fading of the product.

Deshijia PVC Series

Deshijia APVC-A Series

1. Super strong anti-aging

2. Excellent corrosion resistance

3. Excellent weather resistance

4. Excellent thermal insulation, sound insulation, and fire resistance

Installation Technical Guide

1. For roofs installed with our products, a slope of about 20% is recommended. When the span of the building exceeds 30 meters, the slope requirement should reach about 25%.

2. The steel structure materials used for installing our products are recommended to be national standard materials, and their model and grade must meet the load-bearing requirements, ensuring consistency.

3. The ultraviolet light in the installation area should not exceed 50mw/m2 and the ambient temperature should be ≤50°C.

4. Do not directly cover our products on other products with different wave shapes and distances, nor directly cover them on metal tile surfaces, to avoid deformation of PVC materials due to high temperatures absorbed by metal materials.

5. PVC materials have thermal expansion and contraction properties, so the length of a single product should not exceed 10m to avoid excessive expansion and contraction, which may break fixed screws or tear installation holes.

6. The spacing between purlins must be uniform, within 800mm (within the corresponding standard spacing requirements).

7. During installation, personnel are strictly prohibited from stepping on the product across empty spaces to avoid safety accidents or damage to the product.

8. Please pre-drill holes with a pistol drill, using a plastic-specific drill bit. The drill bit diameter should be 2-4mm larger than the diameter of the fixed component (to allow for thermal expansion and contraction of the plastic). The edges of the holes should be kept smooth, avoiding concentrated force, and drilling should be done carefully in cold weather, ensuring the product is well supported underneath.

9. All fixed components should be positioned at the ridge, ensuring that the fixed components are perpendicular to the tile surface. The fixed components should not be overly tightened to avoid deformation of the anti-corrosion tiles and leakage.

10. The number of fixed components must ensure at least 4 per square meter, and waterproof troughs can be added above the fixed components. For installations around the frame, please appropriately increase the number of fixed components and wind pressure plates, ensuring that the anti-corrosion tiles extend no more than 100mm beyond the eaves purlins, and use strip stainless steel to tightly secure the entire frame to prevent the edges from being lifted by strong winds.

11. The horizontal overlap of the product must be done according to the dominant direction of wind and rain. Resin tiles, trapezoidal tiles, high wave tiles, and large round wave tiles should overlap one wave, while small wave tiles should overlap two waves. When the span of the building exceeds 24 meters, three waves should be overlapped.

12. The length of the vertical overlap should be 200mm, and the purlin should be positioned in the middle of the overlap, with two additional fixed screws installed at the overlap.

1. Wave tile extrusion production line

Product use: Our company develops and produces various plastic wave tile extrusion complete sets of equipment, with extrusion raw materials including PVC, PP/PE, PC, ABS, PET, and other types of resins. The products produced are suitable for various usage environments and meet different market demands. Equipment can be customized according to special customer requirements.

Can be used for roofing and wall materials in factories, shopping malls, warehouses, greenhouses, sports fields, construction sites, etc.

Product characteristics: corrosion-resistant, flame-retardant, low-temperature resistant, green and environmentally friendly, etc.

2. Synthetic resin tile extrusion production line

The production line can produce PVC single-layer or ASA/PVC resin tiles.

Product characteristics: weather-resistant, anti-corrosion, insulation, self-cleaning, soundproofing, thermal insulation, and waterproof.

Product use: New rural reconstruction, flat-to-slope conversion, villas, self-built houses in rural areas, villas, tourist attractions, agricultural markets, balcony thermal insulation sheds, etc.

3. High-strength hollow tile production line

The hollow composite tile extrusion production line consists of a conical twin-screw extruder, extrusion molds, shaping systems, traction machines, cutting machines, etc., and can produce single-layer and double-layer hollow tile products.

Product features: thermal insulation, wind and earthquake resistance, fire insulation, lightweight and waterproof, green and environmentally friendly, easy to install, and flexible for use in various fields.

Product use: Agricultural greenhouses, factories, chemical and pharmaceutical industries, sports fields, warehouses, schools, temporary sheds, commercial buildings, etc.

4: FRP fiberglass daylighting tiles/panels production line

Product characteristics: can be customized to be flame-retardant, acid and alkali resistant, corrosion resistant, aging resistant, easy to install, high light transmittance, any coloring, rich in models, and high cost performance.

Product use: Can be used for industrial factory and civil building roofs, wall daylighting, and places with corrosive and dust safety hazards.

5. Fiberglass purlin production line

Product characteristics: solves the corrosion problem of metal purlins, replaces traditional square steel, has good acid and alkali resistance against chemical corrosion environments, lightweight and high strength, aging resistance, and excellent insulation.

Product use: FRP anti-corrosion purlins, building purlins, rolling mill purlins, smelting plant purlins, etc.

6. PVC anti-corrosion gutter equipment

7. Plastic steel edge banding equipment

8. Complete line accessory processing equipment

The introduction and improvement of a series of products have increasingly strengthened the company's advantages in large-scale manufacturing. After more than ten years of rapid development, the Deshiju brand has gained a reputation in the industry and has won high recognition in the market. It has a good reputation among numerous clients and distributors in the construction industry. We do not compete on price with peers but are committed to actions that strengthen the company's advantages in large-scale manufacturing.

Related Products

Welcome your message consultation

Mobile Scanner

Mobile Scanner